Clamshell Die Cutter Repair

Your one-stop service experts.

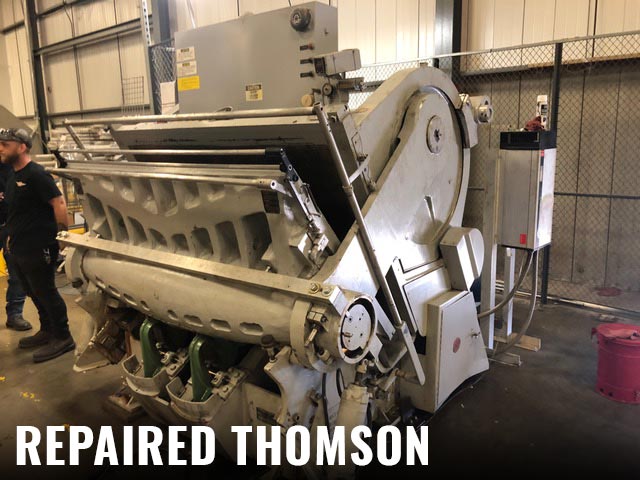

Have an old Thomson that needs parts? We’re your source. A brand new clamshell you want tweaked? Sure. Looking for a specific service, like a Minster Clutch repair? We do that too.

Whether you need minor repairs or a complete press rebuild, our experienced technicians will get you back in production with as little downtime as possible.

In fact, we’ll be in and out of your plant two to three times faster than your local mechanic. That’s because we know clamshell platen presses inside and out, plus we understand die cutting and die cutting processes. It’s an invaluable combination that saves you time and money.

All the services you need…

- Phone diagnosis: Our up-front evaluation saves you an extra plant trip and downtime.

- On-site press assessment: Our technicians identify both current and potential issues.

- OEM service: We’ll rebuild and restore your platen die cutter to OEM specifications.

- Clamshell parts: We provide OEM or high-quality aftermarket parts.

- In-plant service: No need to ship to the factory. We handle all major repairs, including removing the bridge, main gears, air clutch and more.

- Preventive maintenance: Our annual and semi-annual agreements come with detailed reports.

- Brands we service: •Crest •Thomson •Cauhe •Standard •Brausse •IT&M •Imperia •Preco •Titan •Yawa •Saroglia …plus more

- Training and tips. Die making, steel rule die cutting, embossing, foil stamping and new technology like the Soft Cut™ System – we understand the processes and can help improve your productivity.

- Safety updates. We’ll install the latest updates.

- New/used die cutting equipment. If you’re in the market, we can help you find the die cutter you need.

Need Service?

Call us today at 617-306-6886

BEFORE

AFTER

Clamshell Die Cutter Repair

We’ll get you up and running.

Clamshell platen press parts

At Nationwide DCS, we provide a wide range of clamshell platen press parts designed to keep your equipment running smoothly. Our parts inventory covers all major brands and includes hard-to-find components to ensure your press operates at peak efficiency. With our in-depth knowledge of clamshell platen presses, we’ll help you identify the exact parts you need to minimize downtime and keep your production lines running.

Platen die cutter rebuilds and restoration

Our platen die cutter rebuilds and restoration services breathe new life into your equipment, extending its usability and performance. Whether it’s a minor overhaul or a full-scale restoration, we meticulously assess and restore every component. Our technicians are experts in the intricacies of platen die cutters, ensuring that each rebuild meets industry standards for precision and durability, saving you from the cost of a new press.

In-plant service

When you need on-site support, our in-plant service is ready to respond quickly. We understand the time-sensitive nature of production lines, and our technicians work efficiently to get your equipment back in operation with minimal disruption. From diagnostics to repairs, we deliver fast and effective service in your facility, leveraging our experience with clamshell platen presses to troubleshoot and resolve issues on the spot.

Safety Updates

Safety is paramount, and our safety update services ensure your equipment meets the latest standards. We assess your clamshell platen press for potential hazards and install upgrades that safeguard your operators while maintaining performance. Our proactive safety solutions minimize risk, comply with regulatory standards, and promote a safe working environment for your team.

Training

We offer comprehensive training programs to equip your team with the skills to operate and maintain clamshell platen presses confidently. Our training covers best practices, troubleshooting, and essential maintenance tasks, empowering your staff to maximize productivity and prolong the life of your equipment. With hands-on instruction from experienced technicians, your operators gain valuable knowledge to handle your presses safely and effectively.

Maintenance Contracts

Our maintenance contracts offer peace of mind with scheduled inspections and upkeep for your clamshell platen presses. By performing routine checks and addressing wear and tear, we prevent potential breakdowns and reduce unplanned downtime. With a maintenance contract, you’ll have the confidence that your equipment is in top condition, helping you avoid costly repairs and maintain continuous production.

Frequently Asked Questions

What is a hot stamping press?

A hot stamping press is a machine used for printing or decorating various materials such as paper, leather, plastic, and fabric. This type of press uses heat and pressure to transfer a metallic or pigment foil onto the surface of the material. The foil is usually pre-printed with a design or logo. Hot stamping presses are commonly used in the manufacturing of items such as book covers, labels, packaging, automotive parts, and fashion accessories.

We offer hot stamping press / machines from Kensol Franklin

What is a metal stamping press?

A metal stamping press is a machine used in the manufacturing industry to shape and cut metal into a desired form. The press applies force to a set of dies that are designed to create an indentation, cut, or other shape in the metal. This process is commonly used to create components for various industries, such as automotive, aerospace, and electronics. Metal stamping presses come in a range of sizes and capacities, from small manual machines to large automated presses capable of producing high volumes of parts quickly.

We offer hot metal stamping press / machines from Perkins

What is a clamshell die cutting machine?

A clamshell die cutting machine is a machine used to cut various materials, typically paper or cardstock, into specific shapes and sizes. It gets its name because the two halves of the machine open and close like a clamshell, with the die (a shaped blade) and the material being cut placed in between the two halves. When the machine is activated, the two halves come together, pressing the die onto the material and cutting it into the desired shape. Clamshell die cutting machines are commonly used in the manufacturing and crafting industries.

We offer hot clamshell die cutting machines from Thomson Press